A regenerated future is all we can hope for.

If we do not have this, we will have nothing.

But when has mankind not risen to the challenge

...and made an industry of it?

We have enough to be getting on with.

We must now alter our conception of all that has been made.

So that nothing is lost.

There is always more to find, in a thing;

if minds search without needing to already know,

paradise can yet be cultivated,

and it begins with love.

Annie George, 3.12.24.

When speculating on what the future might find us wanting, I think it is safe to say little will change concerning the desires of humans, how those desires manifest, may be open for new interpretations.

Every dystopia ever written acknowledges both widespread deprivation and the enormous wealth garnered in the upper echelons of society. The expression of lived realities all along those social spectrums, reach and yearn for beauty, glamour and sex appeal that reverts the everyday lives, speaking to what people don’t necessarily require to survive, but hunger for and may just need, to want to stay alive.

The Kessler Effect refers to the scenario described by Donald Kessler in 1978, wherein the density of space junk in low earth orbit (LEO) and the instability of the environment could lead to collisions, which could potentially cascade into an unstoppable series of events with one predicted outcome rendering space activities and the use of satellites in specific orbital ranges impossible for generations.

In the age of the Anthropocene, an age defined by human waste and material rendered useless by social attitude, looking to the marginalised areas of the world, the landfills and spaces left swirling in human detritus, and seeing opportunity, material affordances and futures within these histories, is the only way through.

So, a future defined by the cusp of calamity.

A Kessler Future.

“If an alternative society emerges in a period of climate change, it will enact rather than propose or represent, values of caring and well-being... the means used do not so much lead to the ends produced but are the ends.” Malcolm Miles, Eco-Aesthetics

REGENERATION

Designing with regeneration as a core value, considers the conservation of energy above the constraint of time.

A system optimised to integrate resources without wasting any of the energetic potential of materials or processes, can be deemed regenerative.

Emission of carbon is considered a wastage of energy in this model of regeneration.

How this applies to social context is complex, yet straightforward.

A regenerative system does not take more than absolutely required to produce a zero carbon output and meets the criteria of manufacture which optimise the stored energy in all components integrated for future production.

THE BRIEF

Regenerative materials, structures & Aesthetics

Supergreen, ide module

Tutors:

- Fernando Galdon (RCA)

- Stephen Greene (ICL)

- Chandra George to (ICL)

You will have to select an archetype from your category and will develop a manifesto as a starting point. The main focus will be on material use/impact and processes to enable regenerative products. By regenerative we mean landfill waste activation, monomaterial to facilitate recycling, and/or products assembly/disassembly to facilitate its reuse/recyclability.

You will consider both old and new manufacturing techniques. We will explore how we, as designers, can positively influence the balance between the environment vs the harmful manufacturing forces embedded in the implementation of the industrial process. Special emphasis will be given to new local production paradigms and the reimagining of local micro factories.

My bRIEF:

Consider the aesthetic function of the stiletto in relation to its manufacture;

how might I achieve variability in colour and texture, in addition to necessary structural integrity, with a mono material composed of a non-toxic combination of post-consumer materials?

Kessler futures

Stiletto

Considering regenerative manufacture to be the least amount of (carbon-fuelled) modification required to activate the highest potential of a material, I am conducting this research into the behaviours of plastics and biocomposites to ascertain the requirements and possibilities of working with both separately and in combination, with the objective of creating ‘combine’ products that can be effectively deconstructed without degenerating the materials.

For my material explorations I conducted two parallel investigations;

1. How to create a structure for fiberised polypropylene that lends itself to the consumer products

2. Develop a water resistant alternative to plastic derived from entirely non-toxic materials.

The purpose of this research is to grow the potential for recycled plastic to reenter manufacture, post- consumer. With the end goal of creating an alternative to extraction by diverting streams of PP from the landfill and building possibilities for use cases, this experimentation considers the properties of plastic and biocomposites as it relates to combining materials of different compositions without making composites. This is done to optimise the potential of all materials combined, without making composites which would degrade or hinder the future use of those materials.

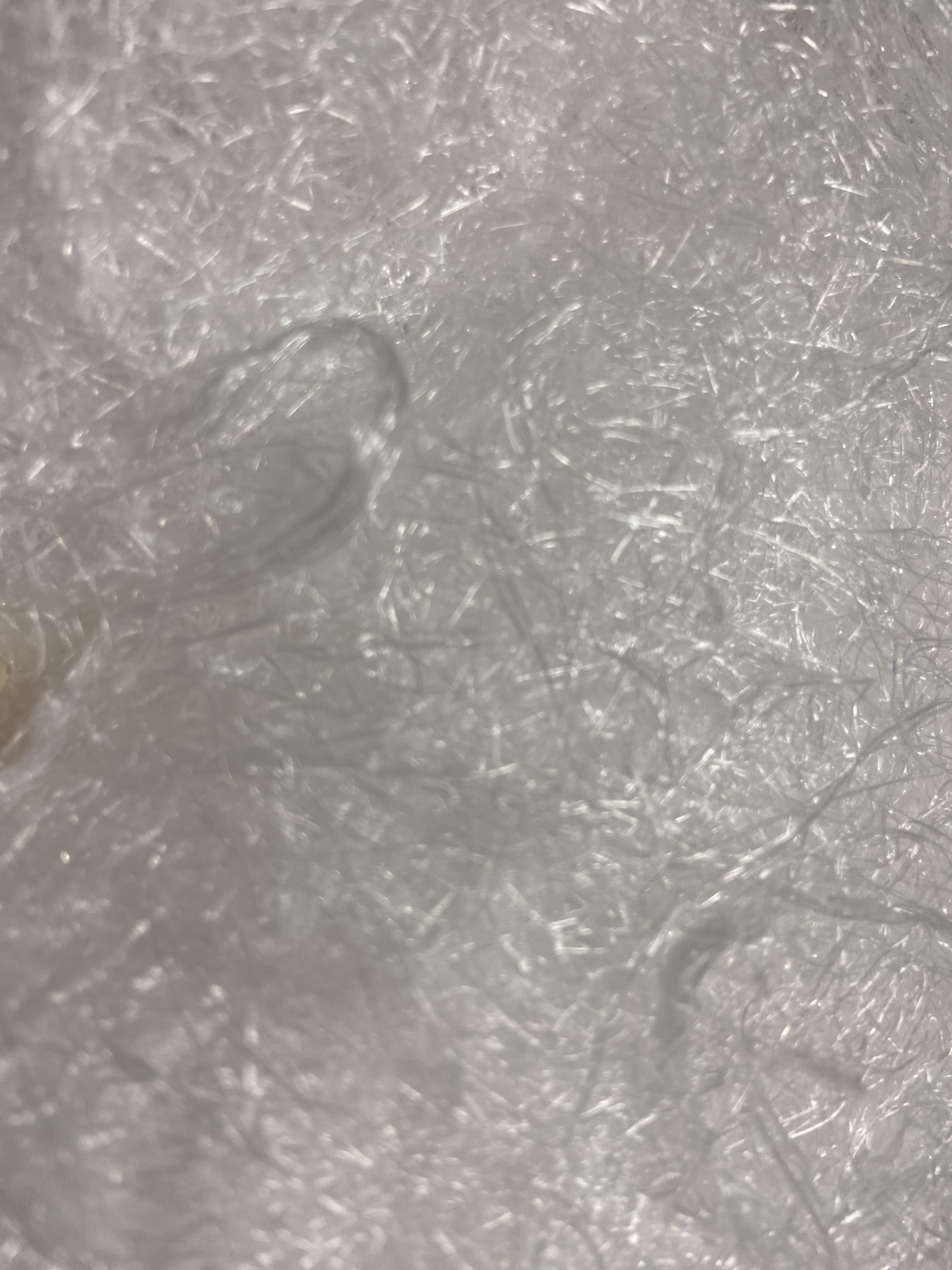

material exploration -- poly floss

Polyfloss is a recycled form of polypropylene that is processed in such a way that it produces a candyfloss-like material.

Method

I set about learning how to spin polyfloss into yarn using a spinning wheel.

Observations

This fluffy texture is good for spinning into usable yarn. long fibers make it relatively durable with good elasticity but the inconsistencies produced in the material during the recycling process make it difficult to produce a consistent thread which, in turn, make it difficult to work with in textiles.

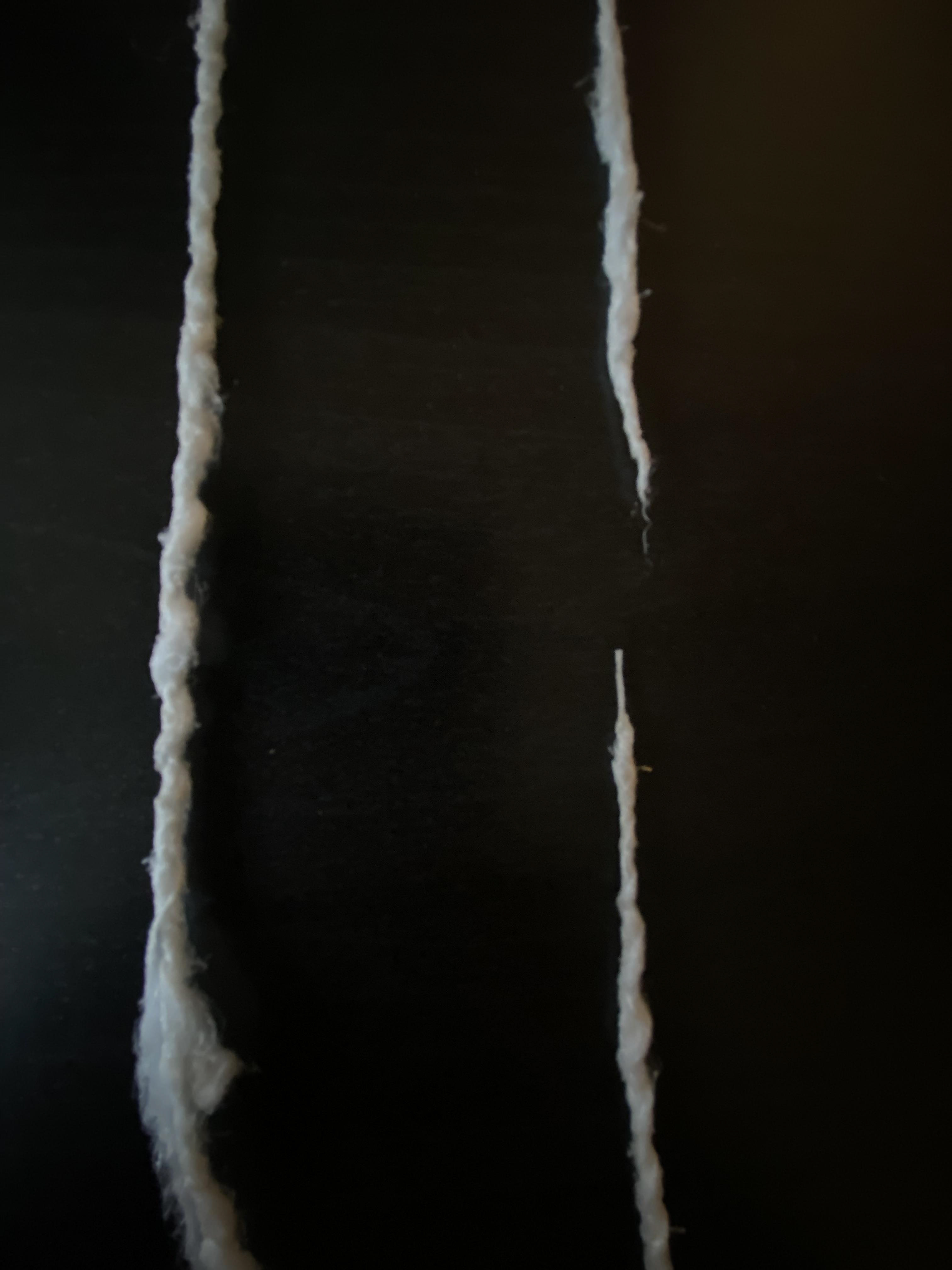

Method

After realising the difficulty posed by the small hard pieces of microplastics that do not entirely fiberize in the recycling process, i tried further heat modification to smooth out the threads. While it created a more uniform thread, the elasticity was compromised and the threads became more brittle and tended to break more easily.

Method

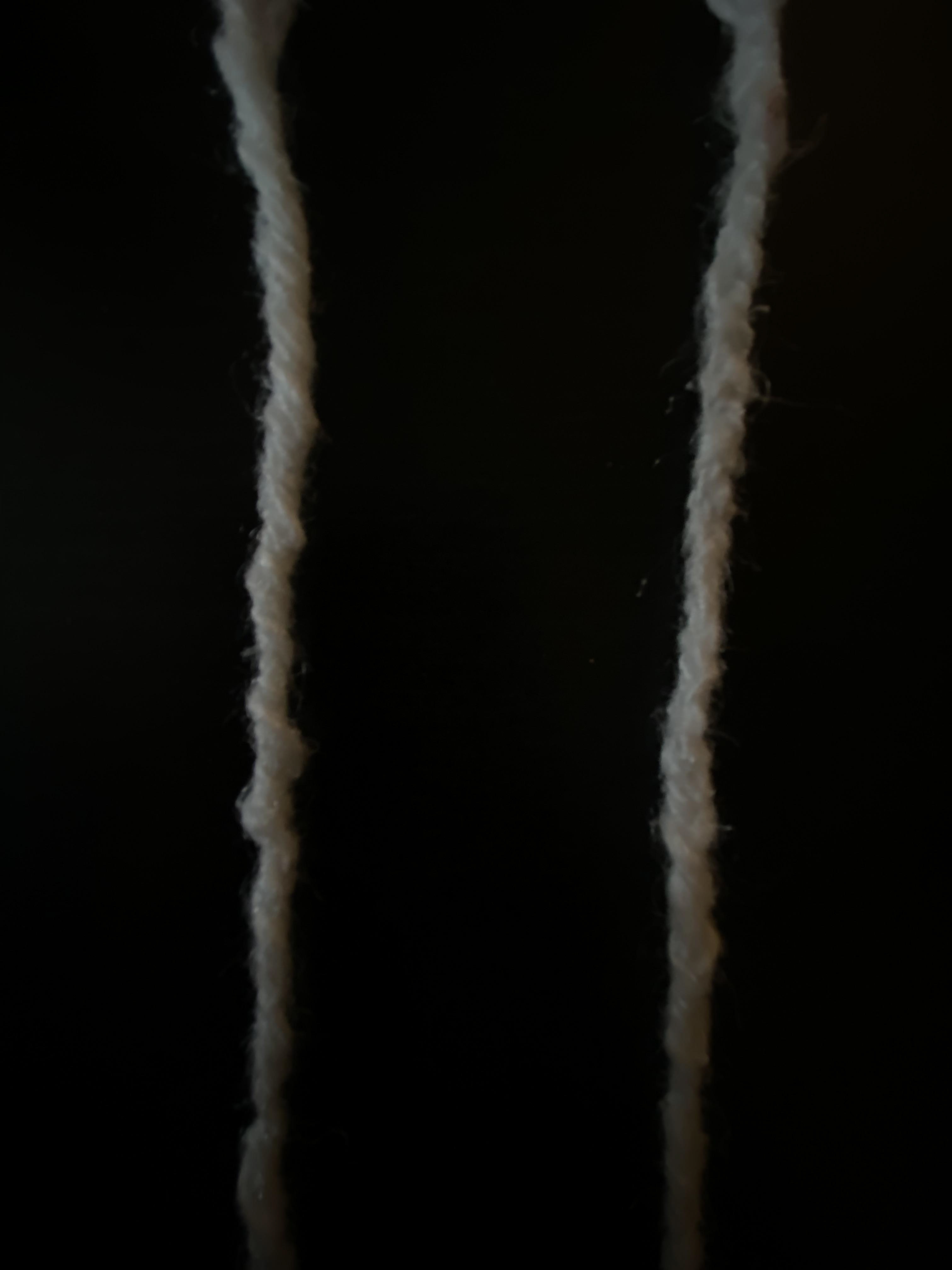

I worked working polyfloss yarn/ polyarn into different plys; single, double and triple.

Observation

As expected, the higher the ply the more tensile strength afforded.

Problem

Still, the main issue with using polyfloss for post-consumer manufacture in a way that does not modify with heat,, is the shedding of microplastics.

Future Testing test

The strength and elasticity of higher ply yarns with evenly applied heat, to seal the exterior while keeping interior flexible.

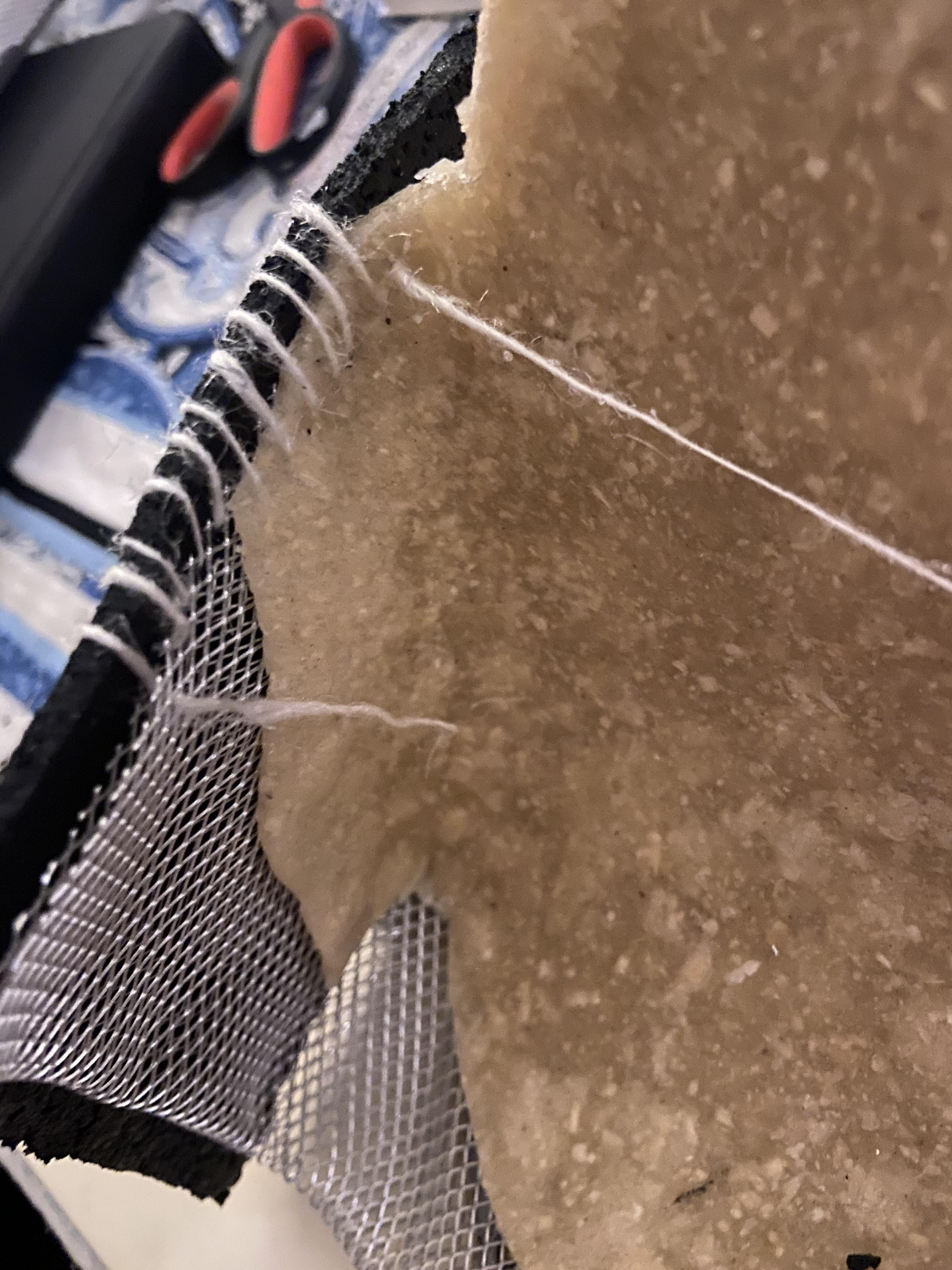

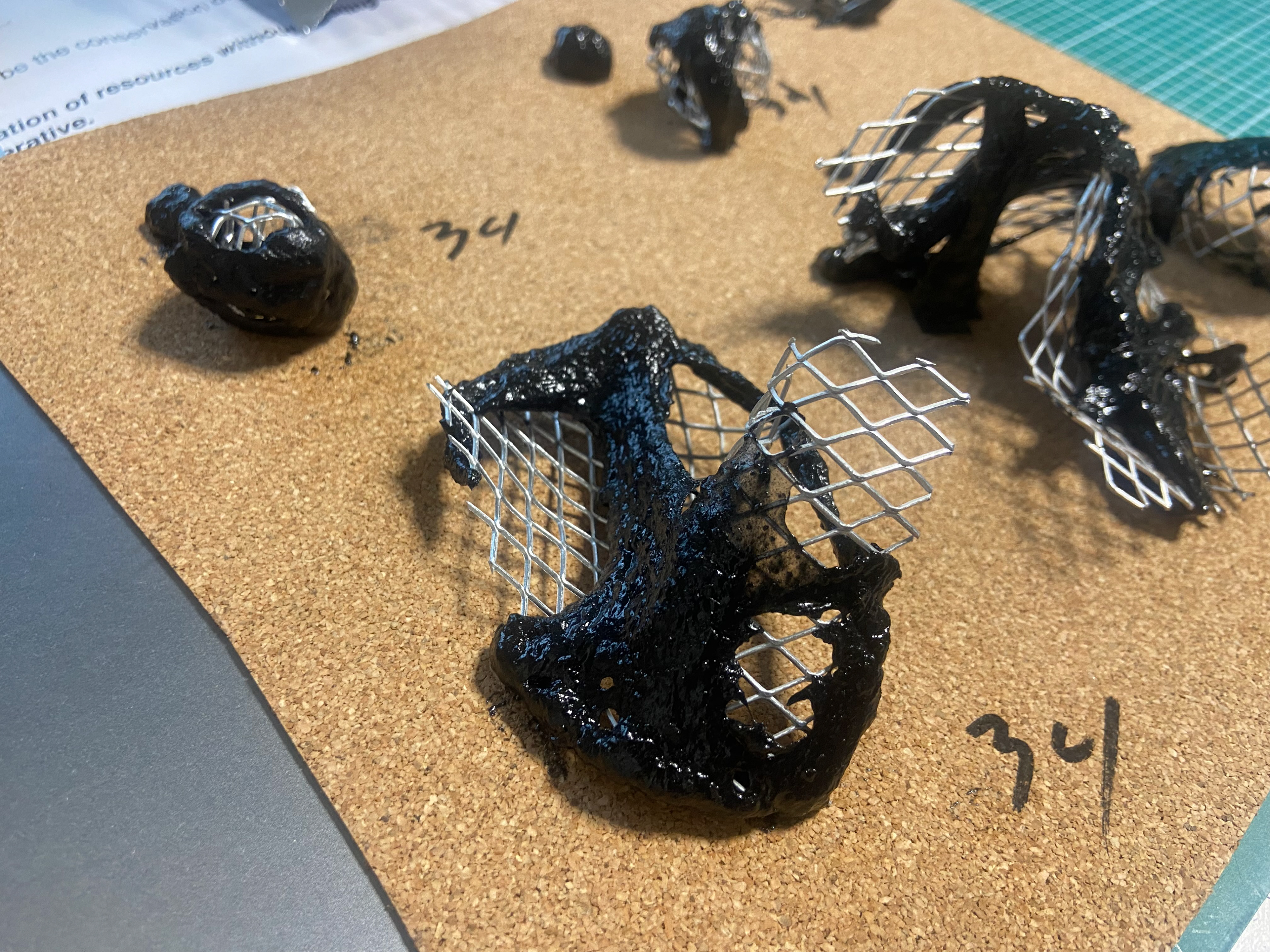

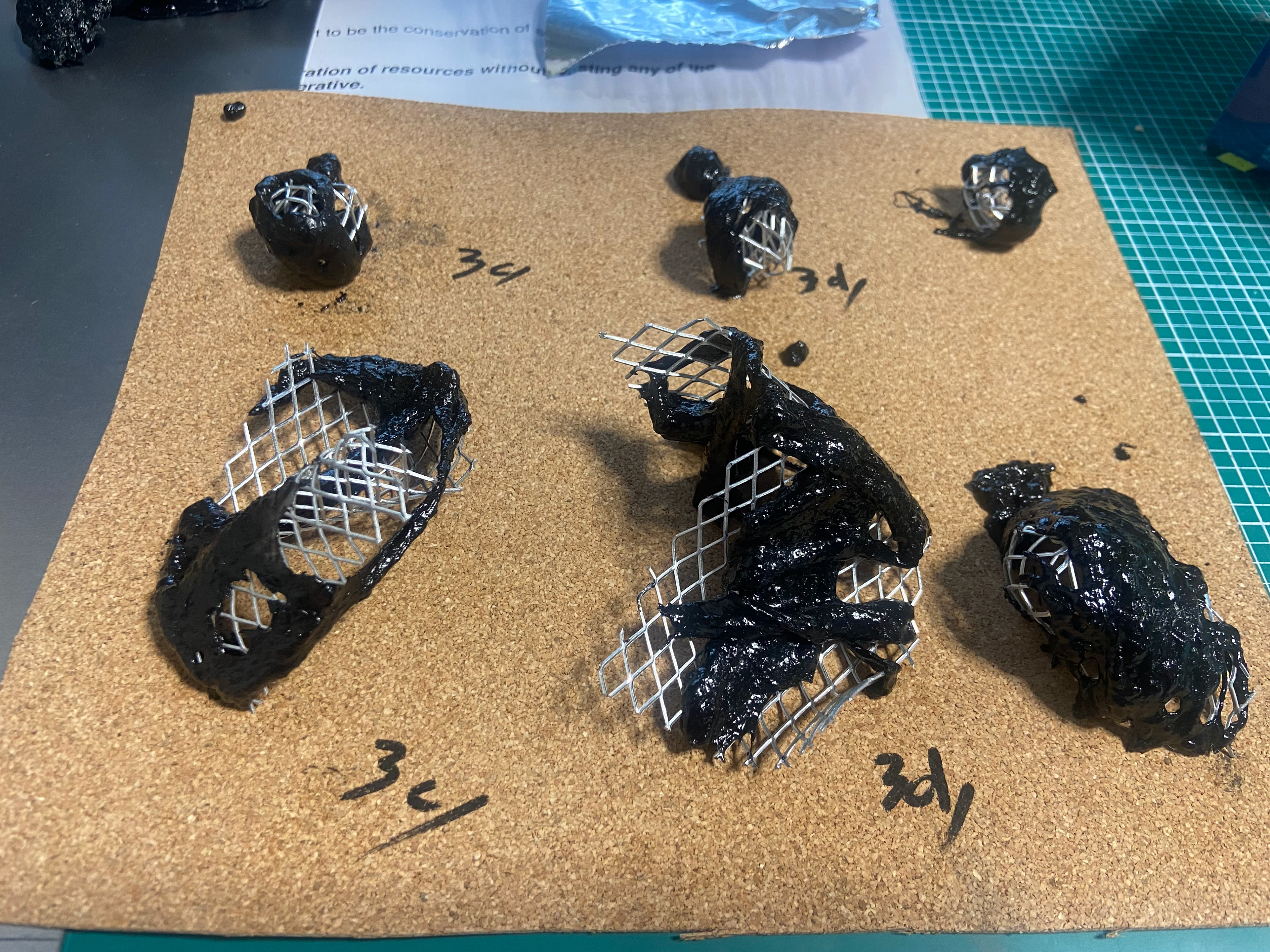

Material Exploration- Biocomposite

Experiment

The process of creating a biocomposite that is water resistant, flexible and sealed (does not leave residue when touched) was challenging, but in the end, successful.

Method

Combining with water was not an option to make a water resistant material so i chose to work with linsed oil, a natural plasticiser. Mix glycerine, vinegar, starch, charcoal and sawdust over heat, then add linseed oil after combined.

Recipe

linseed oil 7ml

vinegar 7 ml

glycerine 15 ml

arrowroot powder 7.09 g

sawdust 1.10g

charcoal 1.06 g

Outcome

I experimented with various adjustments to this recipe but this proved to be the most consistent; equal parts linseed oil, vinegar and starch, double glycerine and equal parts charcoal and sawdust

Reflection

While the texture of this composition was favourable for stretching and wrapping, obtaining and holding a consistent for was not in its properties.

While this made for an interesting application, the requirements for developing a material with structural integrity called for an adjustment in both recipe and process.

Result

A strange material with incredible abilities to adapt to pressure without breaking. Very moldable, does not dry out. Successfully combined linseed oil into emulsion with vinegar, by letting water in vinegar evaporate after setting reaction in motion.

Experiment

The first trials with adding oil after combining the other wet and dry ingredients over heat was successful at achieving an emulsion at a cost of applicability of the material. These trials tested the feasibility of the composition without vinegar so that the ingredients could all be combined at once and poured, and spread into a sheet.

Method

Ingredients are combined cold, spread onto a baking sheet and cooked in over at 150 degrees celsius, for 10 minutes.

Ingredients

linseed oil 8 ml

glycerine 15 ml

arrowroot powder 5.04g

sawdust 1.05 g

charcoal 1.05 g

Outcome

While the material held its shape extremely well, it did not seal sufficiently. Despite not including vinegar, the elasticity of the material was good and it could handle a degree of stretching.

Reflection

The elasticity of the material was favourable, but the residue and texture of the material is not satisfactory.

Experiment

Having achieved a spreadable combination, i needed to figure out how to create an emulsion without the process of evaporating off water before adding oil. Achieving this while keeping to my ethos of using only non-toxic materials was a challenge. I chose a natural detergent, Aritha, as an emulsifier/ surfactant.

Method

To check feasibility i combined over heat on the stove. An emulsion was achieved (7a). So i progressed to oven baking. Ingredients are combined cold, spread onto a baking sheet and cooked in over at 150 degrees celsius, for 10 minutes. (7b)

Ingredients 7a.

linseed oil 5 ml

vinegar 3 ml

glycerine 14 ml

arrowroot powder 5.07g

aritha 3.12g

Ingredients 7b.

linseed oil 5 ml

vinegar 7 ml

glycerine 14 ml

arrowroot powder 7.01g

charcoal 1.19g

sawdust 1.08g

aritha 0.98g

Outcome

While an emulsion was achieved, the consitency was too brittle, lost elasticity and therefore, not applicable.